top of page

SOMA SINUS SODIAL®

Pumpe – Baureihe SCN

SOMA SINUS SODIAL®

Pumpe – Baureihe SCN

SOMA SINUS SODIAL®

Pumpe – Baureihe SCN

SOMA SINUS SODIAL®

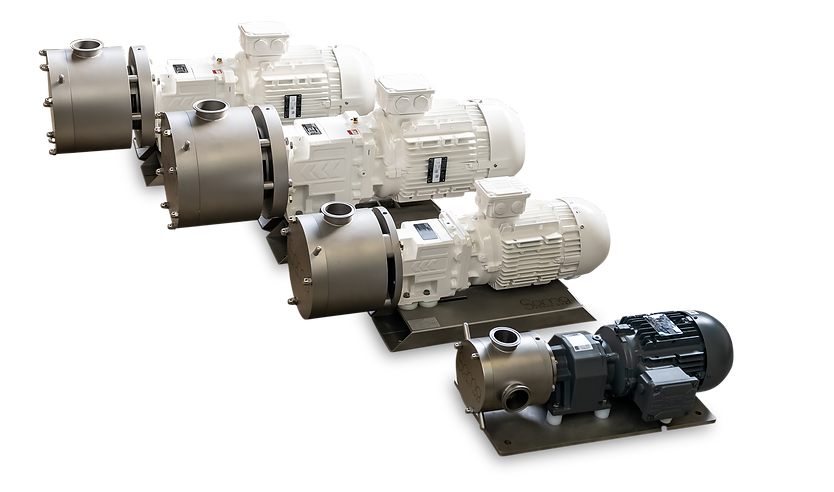

Monobloc Pumpe – SCN-D Series

OPERATING PRINCIPLES

The further development of the SOMA SINUS SODIAL® pump as a monobloc version does not require a bearing bloc, coupling or complex base plate.

The operating principle is the same as for the SCN series, but in this version the SOMA SINUS SODIAL® pump is flanged directly to the drive. Also, here the core of the pump is a sine shaped rotor which is mounted on a drive shaft. It gently and evenly transports the product to be conveyed through four equally divided chambers without any risk of reducing the product quality.

The special feature of the four equally sized chambers is that thus the volume does not change during the pumping process. This function thus also ensures almost pulsation-free conveying.

SOMA SINUS SODIAL® PUMPS

PRODUCT FEATURES

TECHNICAL DATA

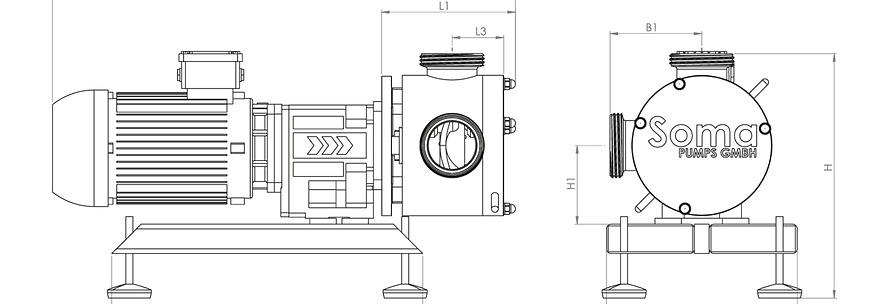

TECHNICAL DRAWING

DIMENSIONS

Our SOMA SINUS SODIAL® pumps are used for a flow rate of up to 90,000 l/h. The pump is equipped with a scraper that takes over the separation of suction and discharge side of the pump, which enables a pressure equalization and thus prevents a backflow. Due to the constantly open suction side, the viscosity of the products is irrelevant. This supports the production of high viscosity products, such as silicones or frozen orange juice concentrate, as well as low viscosity products, such as water-like products. In addition, the pump avoids potential foaming and liquid separation.

The rotor operates in two separate liners made of special material so that the pump housing and cover are not subject to wear. Based on this design advantage, we are able to provide a lifetime warranty on the housing and cover.

The main seal of the SOMA SINUS SODIAL® pump is available in different versions, depending on the application. Various mechanical seals and special seals are offered.

Both the maintenance of the pump and the replacement of wear parts can be carried out by the operator himself in just a few minutes. We will be happy to assist you with any repairs that may be required. The pump can also be cleaned in its installed state in just a few minutes using CIP cleaning and SIP sterilization.

Perhaps the greatest advantage is that all wear parts of the pump are identical to the classic SCN series with bearing bloc. This means that there is no need for separate storage of wear parts, because 100% interchangeability between the SCN-D and SCN series is guaranteed.

In order to achieve optimum efficiency and minimize energy costs as well as pump wear, the pump size must be precisely matched to the process requirements.

Therefore, benefit from our decades of experience and extensive know-how in the field of sinusoidal pumps and let our experts advise you.

Benefits

-

Gentle conveying of the product

-

Consistent and almost pulsation-free conveying

-

Perfect for low and high viscosity products

-

No foam formatio

-

FDA

-

EG 1935-2004

-

ATEX

-

3.1 Stainless steel

-

Lifetime warranty on housing and cover

-

CIP/SIP or manual cleaning

-

Easy maintenance on site

-

Temperatures of max. 180°C

-

Heating or cooling available

bottom of page